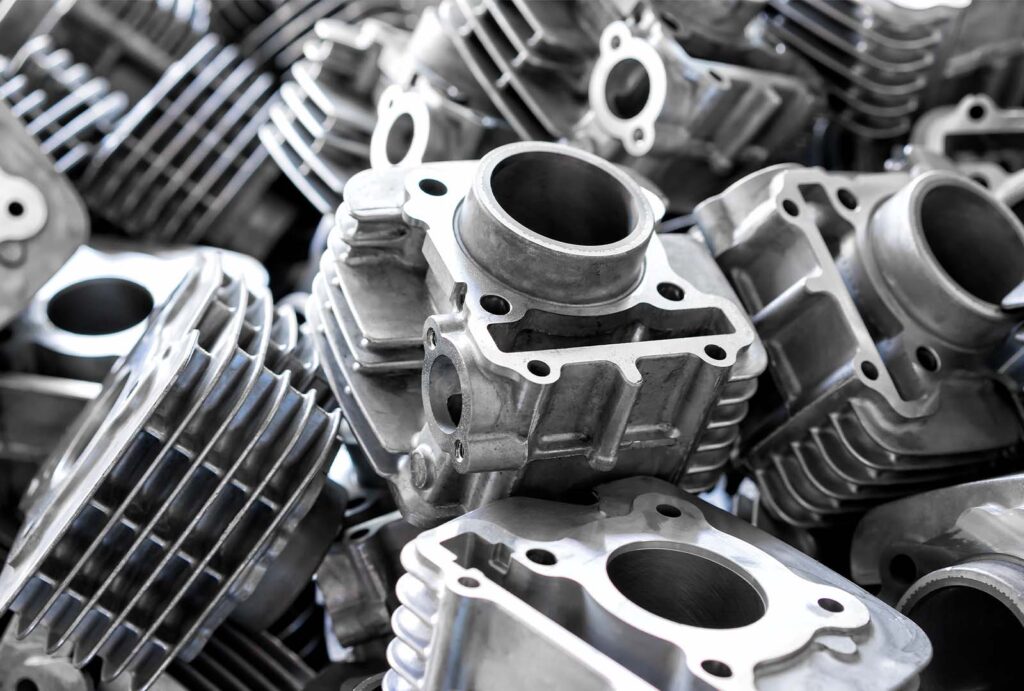

Diecasting in Malaysia has experienced significant growth over the past few decades, establishing itself as a cornerstone of the country’s manufacturing sector. This highly specialized process involves injecting molten metal into steel molds to create precise, high-quality components. The rise of diecasting in Malaysia is driven by the nation’s strategic focus on industrialization, technological innovation, and a commitment to quality. As Malaysia continues to expand its industrial base, the diecasting industry plays a crucial role in supporting various sectors, including automotive, electronics, and consumer goods, contributing to the country’s economic growth and global competitiveness.

The foundation of Malaysia’s diecasting industry is built on strategic government policies aimed at promoting industrialization and economic diversification. Initiatives such as the Malaysian Investment Development Authority (MIDA) and the National Policy on Industry 4.0 have attracted substantial foreign investments and encouraged technological advancements. These policies have fostered an environment conducive to industrial growth, enabling both multinational corporations and local enterprises to thrive. The establishment of dedicated industrial zones with state-of-the-art infrastructure has further cemented Malaysia’s position as a preferred destination for diecasting and other precision manufacturing activities. This strategic focus on creating a robust manufacturing ecosystem has been instrumental in the industry’s rapid development.

Technological innovation is a key driver of the diecasting industry’s success in Malaysia. The adoption of advanced manufacturing technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), has revolutionized the diecasting process. These technologies allow for the creation of complex and precise components with high efficiency and minimal defects. Automation and robotics have also played a significant role in enhancing productivity and consistency in diecasting operations. Real-time monitoring systems and data analytics enable manufacturers to optimize production processes, reduce waste, and ensure consistent quality. Continuous investment in research and development (R&D) ensures that the Malaysian diecasting industry remains at the cutting edge of technological advancements, maintaining its competitive edge in the global market.

Sustainability has become an increasingly important focus within the Malaysian diecasting industry. As global demand for environmentally responsible manufacturing practices grows, Malaysian diecasters are adopting eco-friendly processes and materials. This includes using recyclable metals, implementing energy-efficient production techniques, and adhering to strict environmental standards. The industry’s commitment to sustainability is further evidenced by the pursuit of international certifications and compliance with global environmental regulations. By prioritizing green manufacturing practices, the Malaysian diecasting industry not only meets the evolving expectations of global customers but also contributes to broader efforts to mitigate environmental impact.

Human capital development is another crucial factor driving the growth of the precision machining malaysia industry in Malaysia. A skilled and knowledgeable workforce is essential for maintaining high standards of quality and fostering innovation. Malaysian educational institutions and vocational training centers collaborate closely with the industry to provide specialized training programs tailored to the needs of diecasting operations. These programs ensure that workers are equipped with the latest technical skills and knowledge required to operate advanced manufacturing technologies. Ongoing professional development initiatives further enhance the capabilities of the workforce, promoting a culture of continuous improvement and excellence. The emphasis on human capital development underscores the industry’s commitment to maintaining a competitive and dynamic manufacturing sector.

The diecasting industry in Malaysia has emerged as a vital component of the country’s manufacturing landscape, driven by strategic government initiatives, technological innovation, sustainability efforts, and human capital development. The industry’s growth has positioned Malaysia as a key player in the global diecasting market, supporting a wide range of sectors and contributing significantly to the nation’s economic development. As Malaysia continues to enhance its industrial capabilities and embrace new technologies, the diecasting industry is poised for sustained growth and success. Through continuous improvement and strategic collaboration, the industry will continue to play a pivotal role in shaping Malaysia’s industrial future, ensuring that it remains at the forefront of precision manufacturing on the global stage.