Die casting has emerged as a cornerstone of Malaysia’s manufacturing industry, renowned for its precision, efficiency, and versatility. This process, which involves injecting molten metal into a mold under high pressure, is a critical method for producing intricate, high-quality components. Malaysia’s die casting industry has gained prominence as the country continues to grow as a manufacturing hub in Southeast Asia. With a focus on innovation, sustainability, and meeting the demands of various industries, die casting in Malaysia is driving progress across sectors. The industry’s ability to deliver durable and precise components has positioned it as an essential player in global supply chains.

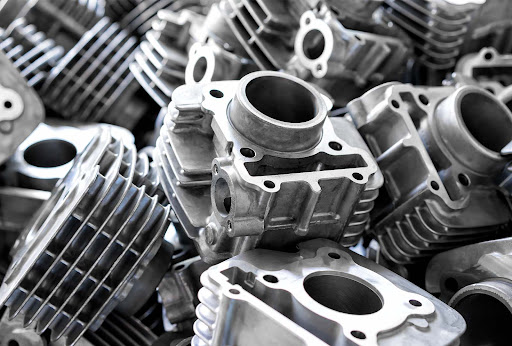

The Malaysian die casting industry caters to a broad spectrum of applications, making it an indispensable part of the nation’s economy. The automotive sector heavily relies on die-cast components for engine parts, transmission housings, and structural elements. These components demand exceptional strength and dimensional accuracy, which die casting provides. The electronics industry also benefits from die casting, using it for enclosures, heat sinks, and other precision parts that support technological advancements. Additionally, sectors like aerospace, medical equipment, and consumer goods leverage die casting to meet their stringent quality requirements. The versatility of die casting demonstrates its critical role in supporting Malaysia’s industrial ecosystem.

Advancements in technology have significantly elevated the capabilities of die casting in Malaysia. The introduction of high-pressure die casting (HPDC) and vacuum-assisted casting has allowed manufacturers to achieve higher levels of precision and efficiency. These techniques are particularly valuable for producing lightweight yet strong components, which are increasingly in demand in industries such as automotive and aerospace. The integration of automation and robotics has further optimized the die casting process, enhancing production speed while maintaining consistency. By embracing these innovations, Malaysia’s die casting industry has positioned itself at the forefront of global manufacturing, ensuring its competitiveness in a rapidly evolving market.

Sustainability has become a key focus in precision machining malaysia industry, reflecting a growing commitment to reducing environmental impact. Die casting is inherently resource-efficient, producing minimal waste compared to other manufacturing methods. Many Malaysian manufacturers are implementing eco-friendly practices, such as recycling scrap metal and adopting energy-efficient equipment. Lightweight die-cast components contribute to the sustainability goals of industries like automotive and aerospace by improving fuel efficiency and reducing emissions. These initiatives demonstrate the industry’s proactive approach to balancing economic growth with environmental responsibility, aligning with global trends toward greener manufacturing practices.

Malaysia’s strategic location and supportive business environment have further bolstered its die casting industry. Situated at the heart of Southeast Asia, Malaysia provides convenient access to key markets across the region and beyond. The country’s well-developed infrastructure, skilled workforce, and government incentives for industrial development make it an attractive destination for investment in die casting and related sectors. Local and international companies alike benefit from Malaysia’s strong supply chain networks and focus on export-oriented manufacturing. These advantages have established Malaysia as a critical player in the global die casting landscape, enhancing its reputation as a manufacturing hub.

In conclusion, die casting in Malaysia represents a perfect blend of precision, innovation, and sustainability, making it a vital part of the country’s industrial landscape. Its ability to deliver high-quality components for diverse applications has solidified its role in supporting various industries, from automotive to electronics and beyond. With advancements in technology, a focus on environmentally conscious practices, and a strategic position in global markets, Malaysia’s die casting industry is well-prepared to meet the challenges of the future. For businesses seeking reliable and cutting-edge manufacturing solutions, Malaysia offers a thriving die casting sector that exemplifies expertise and forward-thinking development.