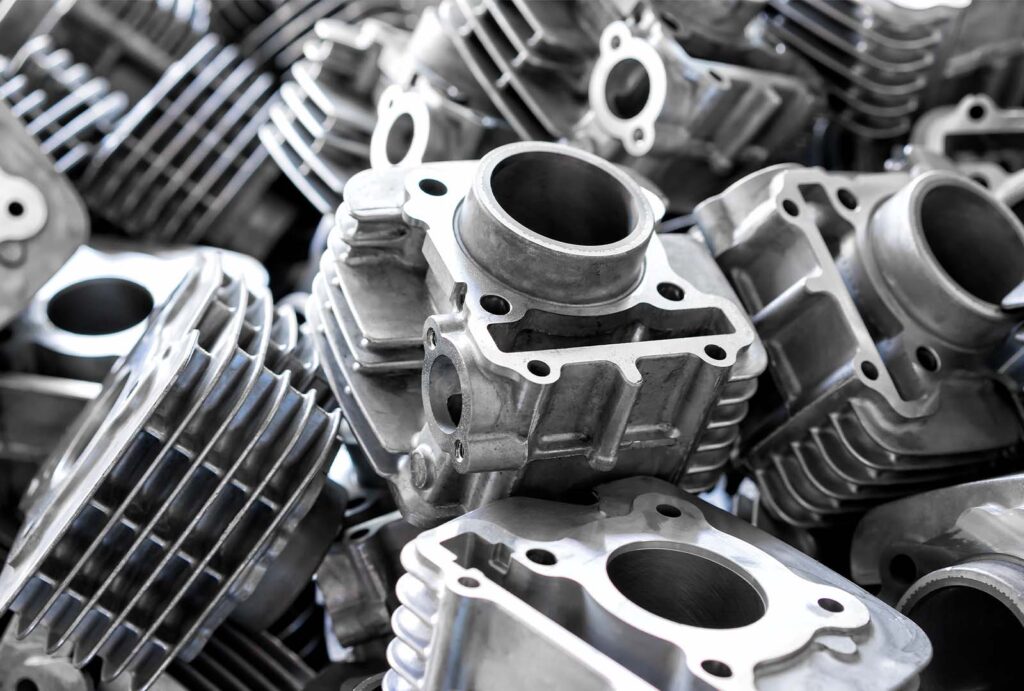

Die casting is an essential manufacturing process that plays a significant role in Malaysia’s industrial landscape. Known for its efficiency and ability to produce complex metal parts with high precision, die casting has become a cornerstone for various industries in the country, including automotive, electronics, and consumer goods. The process involves injecting molten metal into a mold or die under high pressure to produce components with a smooth surface finish and tight tolerances. Malaysia, with its strategic location and growing manufacturing sector, has become a hub for die casting companies that serve both local and international markets. This advanced manufacturing technique has revolutionized the way metal components are produced, offering cost-effective solutions for mass production.

One of the key factors driving the growth of the die casting industry in Malaysia is the increasing demand from the automotive sector. Automakers require high-quality, lightweight, and durable metal components for vehicles, and die casting offers the perfect solution. Through this process, parts such as engine blocks, transmission cases, and structural components can be produced efficiently and with exceptional accuracy. Malaysia’s proximity to key automotive markets in Southeast Asia makes it an ideal location for die casting companies to thrive. Additionally, the rise in electric vehicle (EV) production has further boosted the demand for die-cast components, as these vehicles rely heavily on aluminum parts to reduce weight and improve energy efficiency.

The electronics industry in Malaysia is another major player driving the need for die casting services. Malaysia has long been a global hub for electronics manufacturing, and die casting plays a crucial role in producing precision components used in everything from smartphones to home appliances. The ability of die casting to create intricate, small-scale parts with tight tolerances makes it indispensable for electronic devices where precision is critical. Furthermore, the growing trend toward miniaturization in electronics has led to an increased need for even more refined die-cast components. Malaysian die casting companies are well-equipped to meet these challenges, offering innovative solutions to meet the evolving demands of the electronics sector.

Sustainability and innovation are increasingly important in the aluminum die casting Malaysia industry, and Malaysia is no exception. As environmental concerns grow, many die casting companies in the country are adopting greener practices to reduce their carbon footprint. The use of recycled materials, energy-efficient production processes, and waste reduction techniques are becoming more common in the industry. Additionally, advances in die casting technology, such as the use of more efficient cooling systems and improved mold designs, have helped to increase productivity while minimizing environmental impact. Malaysia’s die casting sector is thus not only contributing to the country’s industrial growth but also aligning with global efforts toward sustainability in manufacturing.

Die casting in Malaysia benefits from a skilled workforce and advanced infrastructure that supports the industry’s expansion. The Malaysian government has been actively promoting industrial growth through initiatives such as tax incentives, infrastructure development, and partnerships with global companies. This has enabled local die casting companies to invest in state-of-the-art equipment and technology, positioning Malaysia as a competitive player in the global die casting market. Moreover, Malaysia’s focus on education and technical training has helped produce a pool of skilled workers who are well-versed in modern manufacturing techniques, further supporting the growth of the die casting industry.

In conclusion, die casting is a vital component of Malaysia’s industrial ecosystem, playing a key role in sectors like automotive, electronics, and consumer goods. The country’s strategic location, growing demand for lightweight and precision components, and commitment to innovation and sustainability make it a hub for die casting operations. As the global demand for high-quality metal components continues to rise, Malaysia’s die casting industry is well-positioned to meet these needs through advanced manufacturing techniques and a skilled workforce. Looking forward, the industry will continue to evolve, embracing new technologies and sustainable practices to maintain its competitive edge in the global market.